Partners involved: TUG (Mayr, WP leader), DTU, UCL, UL, TUB, UOULU, Micronit, iX-factory,nanoMyP.

In WP8, optical sensors based on luminescent sensors and NIR spectroscopy will be integrated into MBRs for precise in situ monitoring and control. These data-rich MBRs will help to establish high-throughput screening, kinetics and characterization of biocatalysis processes.

The workpackages are highly interactively connected and a considerable degree of collaborative contact acrosse the workpackges is necessary in order exploit the potential benefit in this teamwork.

Key parameters monitored and controlled in MBRs are temperature, pH and dissolved oxygen. Temperature is typically measured by means of thermistors or resistance temperature detectors. pH and dissolved oxygen can be monitored by electrochemical means such as integrated ion-sensitive field effect transistor (ISFET) sensor or miniaturized Clark electrodes. Although the integration is demonstrated, electrochemical sensors suffer from drawbacks, such as analyte depletion and electrical interference susceptibility and the requirement of reference electrodes making the integration rather complicated.

In contrast, optical sensor spots are easy to integrate, non-invasive and do not need any reference element. Since they are cheap and can be read out contactless from outside the reaction chamber, they are good alternatives for disposable microbioreactors. Basically, they comprise of an indicator dye embedded into a host polymer. Optical sensors for pH and DO monitoring in bioreactors from medium to large scale and disposable (mini)bioreactors with integrated sensors are available from various companies. Although these sensors were applied in microbioreactors in proof of principle studies they are not ideally suited for the integration in microfluidic devices. To fully exploit optical sensors in microfluidic reactors, they need to offer higher spatial resolution of the local analyte concentrations within the inherently small dimensions of microfluidic systems. In addition, variations in the positioning of commercial optical sensor spots in the typically shallow microfluidic reactors lead to variations in the sensor read-out that are unrelated to actual analyte content, and thus limit the comparison of results between different reactors. Finally, precise positioning accuracy will facilitate analysis of mass transfer in microfluidic reactors, for example by placing the sensors at different locations within a reactor. To achieve this step increase in optical sensing capacity in microfluidic bioreactors – and in all microfluidic devices in general – sensors need to be established from very thin layers and with very high brightness content.

In addition to improved sensor chemistry, simpler read-out systems based on fluorescence imaging for monitoring of parallel reactors are needed to avoid sophisticated multi-channel set-ups with optical fibers. Herein, ratiometric calibration schemes have to be employed to overcome the drawbacks of fluorescence intensity measurements. These include variation of light intensity over the whole area and heterogeneity of the dye distribution in the sensing layer. Efficient ways to eliminate these adverse effects are fluorescent lifetime measurements or ratiometric measurement of two-wavelengths.

Optical nano-sensor particles are attracting more and more attention, since they combine the advantages of a planar sensor with the flexibility of dissolved indicators. Nano-sensors are well-suited for the application in microfluidics since they can be easily injected to the flow minimizing integration efforts. Recently, nano-sensor particles with magnetic properties were presented and their application in monitoring of enzymatic reaction within a microfluidic system was demonstrated.

Research plan

Luminescent sensors for the key parameters dissolved oxygen (DO), and pH will be developed. Herein, sensor layers for monolithical integration, nano-sensor particles, magnetic nano-sensor particles and core-shell nanofibre mats will be elaborated with improved performance compared to existing sensing technology.

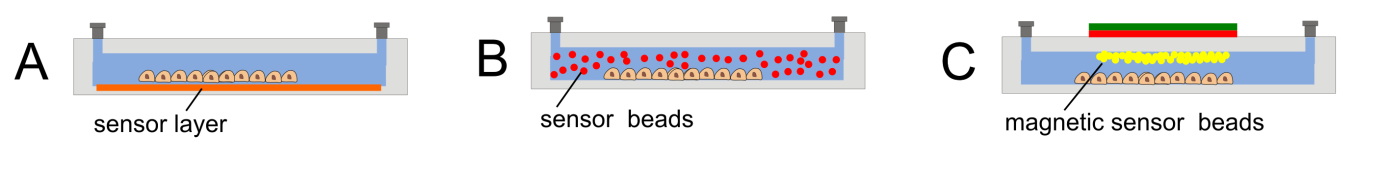

Microbioreactors and integrate sensor layers made of these materials will be fabricated. Sensors will be integrated by three different strategies as illustrated in the figure below: A) planar sensors implemented into the MBR, two different planar sensors will be studied, one based on classic polymeric liquid membranes and other based on core-shell nanofibre mats, B) analyte sensitive nanometre-sized particles that are injected into the microfluidic flow and C) nano-sensor particles featured with magnetic properties. These magnetic sensor beads can be separated in situ by magnetic forces, forming a sensor layer that can be measured by optical means from outside. The obtained sensor “spots” can be collected at distinct locations of the microfluidic chip just by positioning a magnet. Furthermore, NIR spectroscopy for online product monitoring in customized MBRs fabricated will be investigated.

To complete monitoring and controlling, control modules will be developed and a measurement system will be set up based on CCD-cameras for monitoring of several parallel MBRs on one chip. The measurement system will provide a possibility to read out integrated sensor by luminescence life-time or ratiometric measures using the colour channels (blue, red and green) of CCD cameras. In parallel different mediators will be investigated and analytical bio-sensing methodologies will be developed for the electrochemical detection of small molecular weight molecules (e.g. ketones) in complex process sample matrices.